In today’s manufacturing landscape, precision and perfection are paramount. Industries rely on cutting-edge technologies to achieve high-quality results while working with a wide range of materials. One such technology that has revolutionized the cutting industry is waterjet cutting. With its versatility, accuracy, and ability to handle virtually any material, waterjet cutting has become an essential tool for many businesses.

What is waterjet cutting?

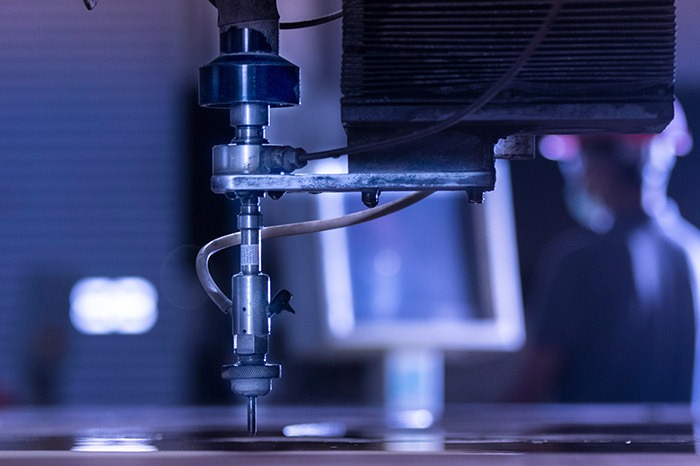

Waterjet cutting is a process that utilizes a high-pressure stream of water mixed with abrasive particles to cut through various materials. It is a non-thermal cutting method, which means there is no heat-affected zone (HAZ) during the cutting process. This characteristic makes it ideal for materials sensitive to high temperatures, such as plastics, composites, and metals, with low melting points.

Versatility across materials:

One of the key advantages of waterjet cutting is its ability to work with a wide range of materials. Waterjet cutting can handle everything from metals like stainless steel, aluminum, and titanium to natural materials like stone, granite, and marble. It can also effectively cut through glass, rubber, foam, and composites, making it a versatile solution for various industries.

Precision cutting:

When it comes to precision, waterjet cutting shines. With modern advancements in technology, waterjet machines can achieve exceptional levels of accuracy. The high-pressure water stream and computer-controlled cutting heads allow for intricate designs and tight tolerances. Whether producing complex automotive parts or intricate decorative patterns, waterjet cutting ensures precise cuts with minimal material wastage.

Benefits of waterjet cutting:

Waterjet cutting offers several benefits over traditional cutting methods:

- The absence of heat-affected zones prevents material distortion, warping, or changes in structural integrity. This makes waterjet cutting suitable for materials that require high dimensional accuracy.

- The process is environmentally friendly, not producing hazardous fumes or waste.

- Waterjet cutting is a cold-cutting process, eliminating the need for secondary finishing operations like deburring or grinding.

Expert waterjet cutting services:

To leverage the full potential of waterjet cutting, partnering with an expert service provider is crucial. These professionals possess in-depth knowledge of the technology and have access to advanced waterjet cutting machines. Expert waterjet cutting services offer a range of capabilities, including handling different material thicknesses, intricate shapes, and large-scale projects.